Failure Mode and Effects Analysis (FMEA) is one of the most effective methods in quality management for identifying risks at an early stage and minimizing them in a targeted manner. In combination with an AI-supported CAQ system, its potential can be exploited even more efficiently.

What is the FMEA method?

Failure Mode and Effects Analysis (FMEA) is a method for detecting sources of failure before they arise, identifying their triggers and consequences and evaluating them. The data obtained can then be used to define appropriate preventive action. In this way, FMEA improves the quality, reliability, and safety of products and processes while helping to reduce time and costs in development and production.

The FMEA method is mainly used in the automotive and aerospace industries, where it is applied for the most part in the development of technical products. However, it is also becoming increasingly important in other branches of industry, particularly in mechanical engineering.

FMEA can be divided into different types, the two most important being:

- Design FMEA (DFMEA): Analyzes possible failures in product design with the aim of developing a flawless product.

- Process FMEA (PFMEA): Examines risks in the manufacturing process to ensure flawless production or manufacturing.

Identify errors before they occur

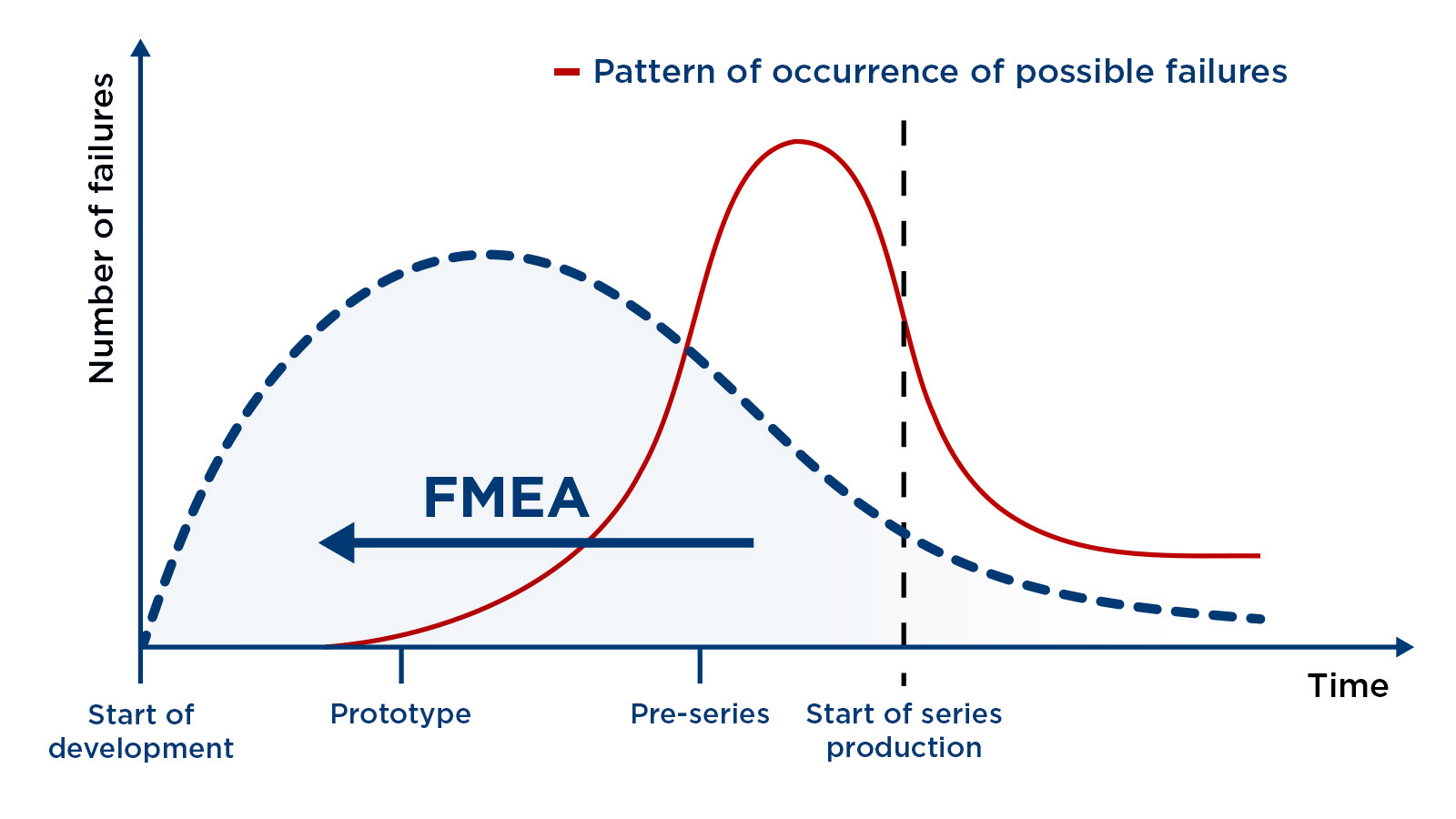

Failure Mode and Effects Analysis helps to identify potential risks before production even begins. By identifying sources of failure in the product or process at an early stage and planning appropriate action, defects can be effectively avoided. In this way, the occurrence of potential failures is shifted towards the start of development, which helps to ensure that they can be rectified at an earlier stage.

The FMEA method identifies potential failures and risks early on in the development phase, shifting their occurrence toward the start of development (Source: FMEAplus Akademie).

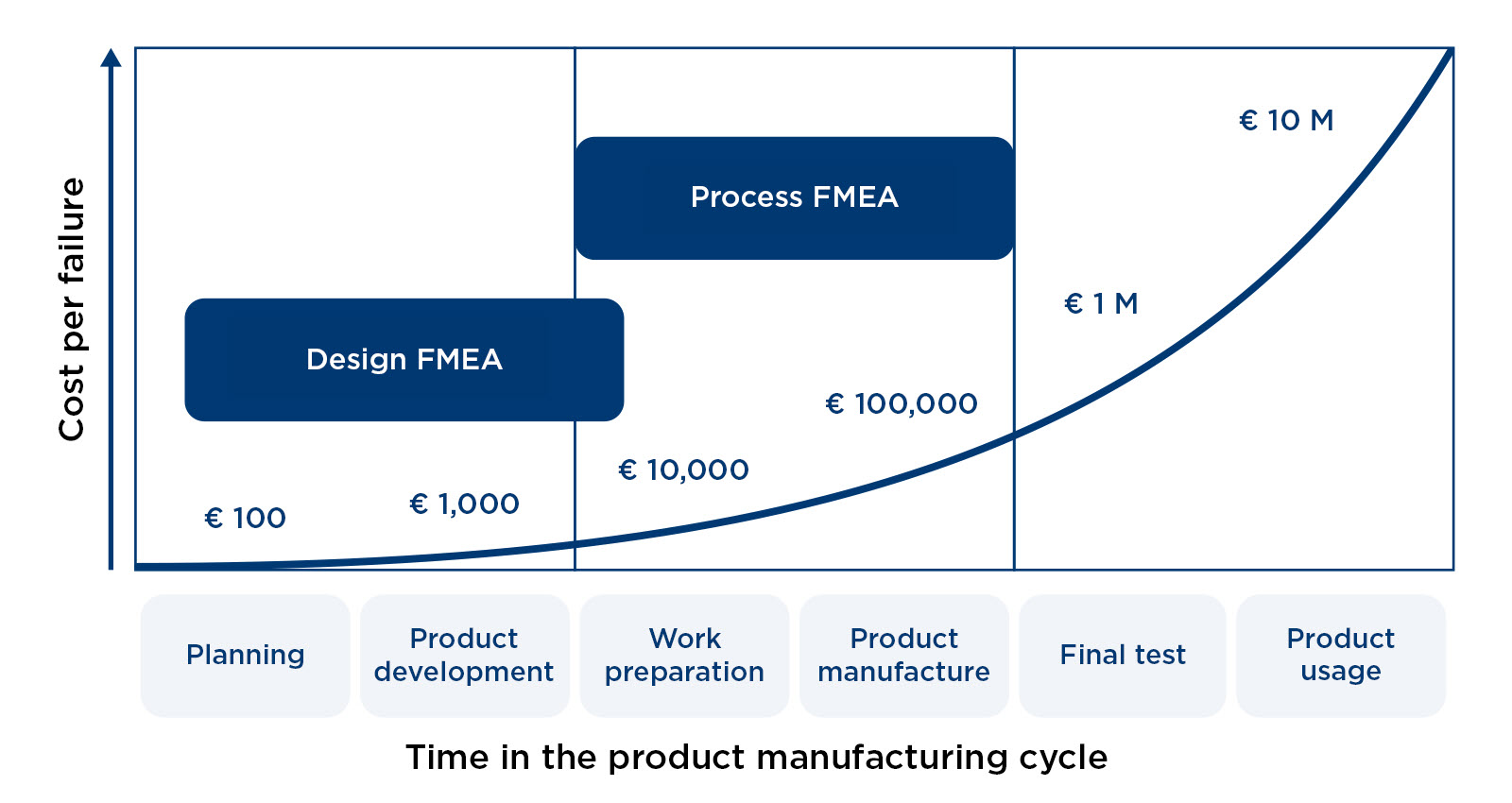

The earlier a failure is detected in the development process, the cheaper it is to fix. If discovered in later phases, the financial outlay increases exorbitantly. This is illustrated by the so-called rule of 10 of error costs: This states that the cost of rectifying a defect increases approximately by a factor of 10 with each development phase.

The cost of fixing failures increases approximately by a factor of 10 for each phase of a project that a failure goes undetected (Source: FMEAplus Akademie).

FMEA is therefore an important tool for ensuring quality from the outset, increasing technical reliability, and reducing high correction costs later on.

FMEA vs. 8D method: Prevention instead of reaction

FMEA has important similarities with the 8D problem-solving method, which is also used in quality management. In both methods, people work together in interdisciplinary teams, investigate the causes of failures, and then derive mitigating action. The significant difference between the two approaches, however, is that FMEA is preventive, i.e., it addresses potential defects, while the 8D method deals with problems that have already occurred.

Use FMEA efficiently with an AI-supported CAQ system

Many companies use common spreadsheet programs such as Microsoft Excel to compile FMEA. However, manual data entry makes this very time-consuming. In addition, FMEA specialist software (which often exists as a stand-alone solution) makes it difficult to use the information seamlessly and for further purposes, for example in the course of a quality control plan or for managing versions.

When it comes to digitalizing important data and the associated workflows, it is therefore advisable to use an AI-supported CAQ system that has its own integrated FMEA module. This offers the opportunity to automate the creation process as far as possible using ready-made modules and to assign upcoming tasks directly to internal and external responsible parties via workflows.

Artificial intelligence, in turn, supports automated risk analysis, recognizes patterns in failure data, and proactively suggests action to prevent them. It also speeds up the assessment of risks, facilitates the prioritization of action, and ensures consistent, transparent decisions within the team. This not only makes FMEA faster and more accurate, but also allows it to be integrated into existing quality processes in a sustainable manner.

Another advantage is the link to other CAQ software modules such as the 8D method, test planning, audits, and complaint processing.

The FMEA process and where AI can help

A globally uniform standard was created in the form of FMEA harmonization by the AIAG (Automotive Industry Action Group) and the VDA (German Association of the Automotive Industry). The standard provides for a systematic approach in the following seven steps.

1st step: Project planning and preparation (scoping)

The first step is to determine the team, define the objectives and scope, and plan the project.

✨ How AI helps:

- AI learns from the analysis of past projects which specialists have which skills and, after the desired criteria have been entered, suggests the most qualified experts.

2nd step: Structural analysis

In the structural analysis, the FMEA team visualizes the scope defined in the first step and presents it clearly. It breaks down the objects to be examined into their individual parts and organizes them into a structure tree for clarity.

✨ How AI helps:

- AI suggests suitable elements within the specified structure.

3rd step: Function analysis

The aim of this phase is to build an understanding of the product or process being examined. Functions of the system elements or workflows to be considered can be derived and visualized from requirements, experience, or the specifications.

✨ How AI helps:

- Text recognition and semantic mapping from documentation or technical drawings.

4th step: Failure analysis

This step involves identifying and evaluating possible sources of failure in a product or process. The aim is to identify and record potential failure modes, their causes, and their effects.

There are four basic failure modes:

- No function: Complete functional failure

- Partial function: Only fulfills part of its function

- Intermittent function: Only works sometimes

- Unintended function: Something unexpected occurs

The Ishikawa diagram (also known as a cause-and-effect diagram) is an important tool for graphically representing the relationship between causes and their resulting effects. This helps to visualize and analyze possible causes of a failure in the individual categories. This enables those responsible to take targeted action to remedy the defect.

✨ How AI helps:

- AI analyzes historical failure data (e.g., from complaints, 8D reports) and offers suggested values (ideas) to identify initial malfunctions.

- Chat with AI to identify typical failures in similar products or processes.

5th step: Risk analysis

Based on the failure analysis, the responsible persons assess the probability of occurrence and discovery as well as the impact of the respective defect or cause. The action priority (AP) is then derived from these factors. Depending on the calculated value, this can be either “high,” “medium,” or “low,” indicating how urgently action needs to be taken to reduce or eliminate a particular risk.

The risk analysis forms the basis for action to prevent failures and, consequently, for product or process optimization. In FMEAs harmonized according to AIAG and VDA, it replaces the previous risk priority number (RPN).

✨ How AI helps:

- Suggestions for prioritizing the AP based on experience and real field data.

6th step: Optimization

Based on the previously determined action priority, the team identifies proposed solutions to reduce risks and then re-ranks them. This optimization process is repeated until all risks are at an acceptable level, for example from “medium” to “low.”

✨ How AI helps:

- AI automatically derives suitable mitigation actions from previous FMEAs that have already proven effective in similar cases.

7th step: Results documentation

In the final step of an FMEA project, the results and the process are documented. This includes all decisions made, critical failures, their causes, and specific risks.

✨ How AI helps:

- AI can derive valuable “lessons learned” from previously defined actions and their effectiveness, which serve as intelligent decision-making aids in future risk analyses with similar problems.

Take FMEA to a new level with AI functions

FMEA is a proven tool for identifying and avoiding failures at an early stage, before they occur in production or at the customer. However, it only reveals its full potential in combination with smart, AI-based CAQ software: Artificial intelligence accelerates analyses, recognizes patterns, and suggests targeted action.

In addition, AI continuously learns from existing projects and supports future development projects even more effectively by offering proactive risk assessments, optimized suggestions for mitigating action, and early detection of recurring weaknesses.

With the help of an AI-supported CAQ system, FMEA becomes not only more efficient but also more intelligent, contributing significantly to sustainably improving safety and quality requirements in product and process development and to reducing failure costs.