The relevance of Artificial Intelligence (AI) in quality management is growing constantly, e.g. in problem-solving approaches such as the 8D method. The use of an AI-supported computer-aided quality system improves efficiency, accuracy, and speed in the course of creating an 8D report, which ultimately leads to a significant increase in product and process quality.

More efficient quality management thanks to Artificial Intelligence

In some specific areas of application, Artificial Intelligence is already more powerful and efficient than humans. This applies in particular to routine processes such as assigning or classifying documents, analyzing large amounts of data, capturing patterns, speech recognition, or natural language processing (NLP), and translation.

AI can also make a significant contribution to improving the efficiency and effectiveness of quality-relevant processes in quality management through its diverse areas of application, e.g. in proactive error detection and prevention, or in the prediction of similar quality problems and failures. These advantages of AI are particularly evident in the applied 8D problem-solving method.

Optimized troubleshooting through AI support in the 8D process

The 8D method is a team-oriented solution approach for processing complaints that occur either internally or externally between suppliers and customers. The resulting 8D report contains eight disciplines or process steps that are required when processing a complaint in order to trace errors back to their causes and permanently prevent them in the future.

The highly regulated formal processes associated with 8D reports usually require a great deal of expertise on the part of quality managers. An AI-supported 8D process in quality management extends the conventional eight-step plan for problem solving by relevant AI technologies in order to achieve more efficient and precise results. It is important to understand that AI only provides suggestions for all process steps – the final decision is always made by humans.

Below you will find a list of some of the ways in which AI can support an 8D process:

Performing a risk assessment

This upstream measure makes it possible to identify the severity of a defect and determine the extent to which an 8D process is required. This involves accessing a “lessons learned” collection (knowledge database) from past projects in order to assess and categorize the risk and determine the urgency of action.

This is where AI comes in:

- AI provides a list of defects that indicate a similar problem.

- These defects and their elimination can contribute to the assessment of the risk based on possible causes and actual or simulated consequences.

D1 – Form a team to solve the problem

Ideally, the team members have sufficient process and product knowledge to analyze the problem for its root causes, initiate corrective actions, and monitor their effectiveness.

This is where AI comes in:

- By analyzing past projects, Artificial Intelligence learns which specialists have which knowledge. Based on these values, AI suggests the best-qualified experts for each step of the 8D process.

- In addition, the AI determines default values for scheduling the 8D process.

D2 – Describe the problem

The problem must be defined as precisely as possible: the core of the problem must be worked out and quantified.

This is where AI comes in:

- Using algorithms such as image recognition, AI automatically finds and classifies defects or deviations in products.

- In addition, it is able to precisely define the problem and generate a data summary for documentation purposes.

D3 – Take immediate action

Even before the actual search for the causes, immediate measures are needed to prevent possible damage.

This is where AI comes in:

- To prevent the problem from spreading further, AI provides suggestions for immediate measures that were carried out when similar defects were rectified.

- AI determines timeframes and deadlines as well as responsible persons for documented implementation.

D4 – Determine causes of errors

Causes of errors are searched for and the most likely cause(s) is/are identified and verified through experimentation, tests, and comparison.

This is where AI comes in:

- Artificial Intelligence is able to analyze large amounts of production data in a short period of time in order to identify patterns and causes of quality problems.

- AI provides suggestions for the appropriate root cause analysis, such as the 5-why method or the cause-effect diagram (Ishikawa diagram), which were used to eliminate similar defects.

D5 – Plan corrective actions

The next step is to take appropriate precautions to prevent the error from recurring. A subsequent effectiveness test proves whether the problem described in D2 has been eliminated.

This is where AI comes in:

- Based on historical data and analyses, AI can predict which actions are most effective in order to solve the problem. These values support the specialists in planning an efficient course of action.

- AI determines timeframes and deadlines as well as responsible persons for documented implementation.

D6 – Introduce corrective measures

If it is shown that the concept defined in D5 is effective, its permanent introduction follows – as well as the removal of the immediate measures taken in D3.

This is where AI comes in:

- Artificial Intelligence provides suggestions as to where else in the company the problem could occur and informs the people responsible about the process for implementing corrective measures.

D7 – Prevent error recurrence

Suitable prevention steps sustainably prevent the same or similar errors from occurring again in the future. The effectiveness of the measures taken – such as increasing the test accuracy – is then monitored over an appropriate period of time.

This is where AI comes in:

- Artificial Intelligence provides suggestions for preventive measures that were implemented when similar defects were rectified.

- AI provides suggestions for adapting or expanding the Failure Mode and Effects Analysis (FMEA).

- AI determines timeframes and deadlines as well as responsible persons for documented implementation.

D8 – Conclude the troubleshooting process

To conclude the process, it is important to document all the knowledge gained from the eight process steps so that it can be used for similar, future projects.

This is where AI comes in:

- The AI is able to derive important findings (“Lessons Learned”) from the set immediate and preventive measures, which are available for the elimination of future, possibly similar errors/deviations.

- The implicit learning of the AI takes place without any additional manual effort.

Overall, the use of Artificial Intelligence in the 8D process helps to improve the efficiency, accuracy, and speed of problem solving, thereby increasing the quality of products and processes while also reducing costs.

The importance of an AI-supported CAQ system

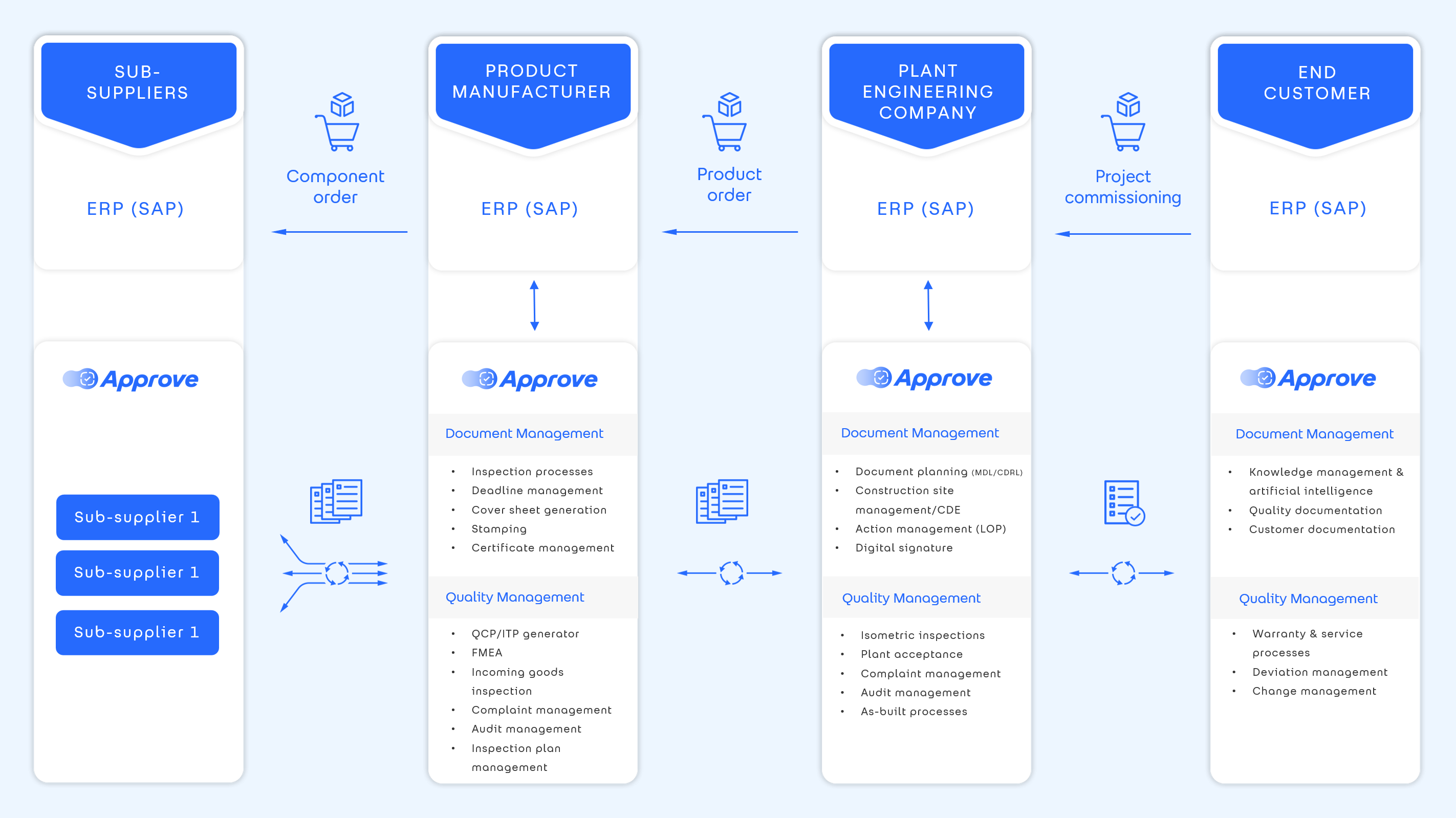

The 8D method really comes into its own when the associated processes are digitized with the help of a cross-plant, AI-supported computer-aided quality system (CAQ system) such as Fabasoft Approve. A CAQ system digitizes quality-relevant processes along the entire value chain and offers the opportunity to quickly involve not only internal members but also external parties, such as suppliers or customers, in these processes.

This networking of all information ensures that everyone involved in the 8D process is working with the latest version across the company. This leads to a fully automated and location-independent complaints management process that fully utilizes the strengths of AI and remains traceable at all times.

The key role of AI in quality management

Today's digital world requires a quality management system that's not only looking inwards, but also outwards. This includes end-to-end processes that cover all steps from the initial inquiry to the final provision or delivery and strive for seamless integration of all parties involved. By involving suppliers and sub-suppliers into important processes, new sources of information are created that can be used to optimize core processes.

Approve covers processes across the entire supply chain.

An AI-supported computer-aided quality system offers the opportunity to raise quality-relevant processes in your company to a completely new level. This can be seen clearly in the 8D process, where AI functions boost efficiency, increase accuracy, and enable data-based decision-making. In this way, an AI-supported CAQ system makes a lasting contribution to quickly eliminating errors and permanently preventing their recurrence.