Technical manuals are a key deliverable for manufacturing companies, whether for the handover of complete plant documentation or for the commissioning of complex machines. This is because they contain important information on the operation, safety, and maintenance of plants or machines. However, creating them is often time-consuming, lacking structure, and prone to errors.

This article wants to show how structured manual generation can be significantly simplified with document management software such as Fabasoft Approve and which benefits this provides for companies.

The typical challenges in manual creation

For many companies, especially in highly regulated industries such as energy supply, technical manuals, maintenance documentation, and other collections of information are an indispensable part of the documentation they provide to their customers as part of the project. However, maintaining hundreds or even thousands of documents, as is common with the documentation of machines and systems, can quickly become confusing.

One of the biggest pain points is that there is often no clear overview of which documents have already been checked, where feedback is still pending, or which documents are still unprocessed. When coordination takes place via email or various share file systems, the context may be lost quickly. This leads to delays, double work, and a lack of transparency.

The structured generation of a manual using document management software such as Fabasoft Approve offers a practical solution. It makes it possible to bring together technical information from different sources – such as suppliers, conversion projects, or maintenance documents – in one place, to check it systematically, manage versions, and make it all available in a targeted manner.

How generating a manual works with Fabasoft Approve

Structured, rule-based generation of a manual in Fabasoft Approve ensures that all relevant documents are collected in one common storage structure and organized thematically by project. This structured collection forms the basis for subsequent steps such as targeted searches, filtering by content, or checking and updating documents.

The idea behind this: All important documents, such as operating instructions or technical drawings, are stored in such a way that they appear in the manual exactly where they belong. Instead of combining individual PDFs into one huge document, individual manual volumes, chapters, and subchapters can be created within a manual, into which the respective documents are sorted. For example, a chapter entitled “Safety Regulations” contains all relevant documents.

Reusable templates

A particular advantage is the possibility of creating complete manual structures as templates only once and reusing them as often as necessary for similar projects. This is not only time-saving, but it also ensures uniform structures, especially for frequently recurring product types such as pumps, motors, or standard systems.

Customer-specific templates and text modules

In addition, customer-specific templates and text modules can be stored that already contain all relevant metadata, such as KKS numbers or DCC references. These modules can be used flexibly in different places in the manual or integrated into accompanying documents such as lists of measures and official letters. The result is a consistent data basis that reduces maintenance effort and minimizes sources of error.

Automatically generated cover sheet

The visual design can also be standardized. Whenever needed, the system automatically generates a cover page for each manual that is individually tailored to customer requirements, including a suitable layout in the corporate design. This quickly creates easy-to-maintain documentation that remains up-to-date, clear, and easy to find at all times.

Coordination processes with suppliers and customers

Close coordination between suppliers, manufacturers, and customers is essential when creating technical manuals. Suppliers often provide important documents such as operating instructions, test reports, or technical drawings for individual components, which the manufacturer must check, supplement, and integrate into the manual. At the same time, customers – such as plant operators – can provide feedback on content, request missing information, or suggest corrections.

Fabasoft Approve supports this process by integrating all participants into one structured workflow. This makes it clear at all times which documents have already been approved, where feedback is still pending, and which content needs to be revised.

Sending a manual volume by business letter

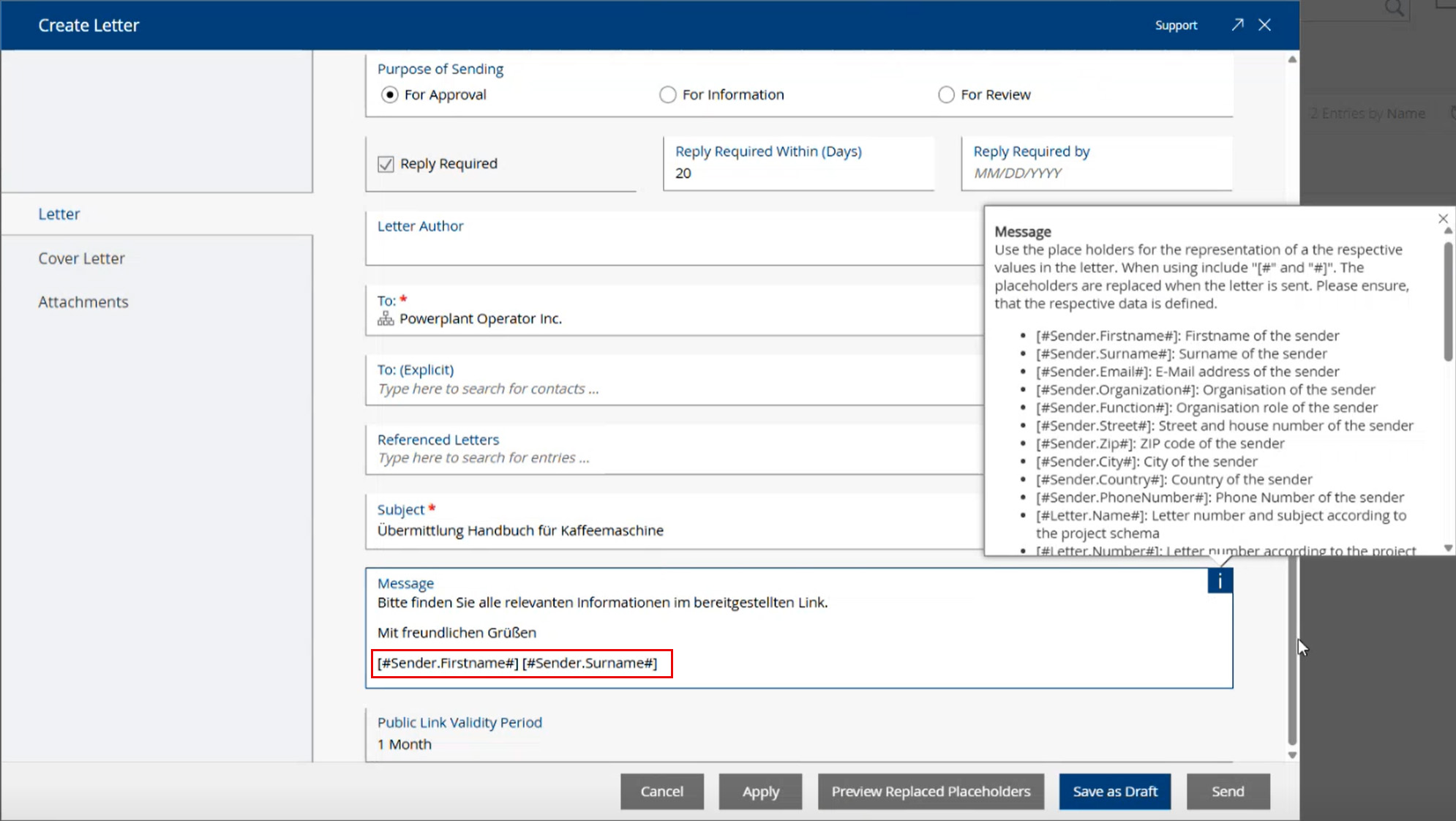

Part of this coordination process is also the option of sending a complete manual volume in the form of an official business letter to a defined recipient. Standardized templates are used for this purpose, which the software automatically fills with the relevant data and includes the required documents (e.g., safety specifications or technical drawings) as attachments. The transmission itself takes place directly in the system, eliminating the need for insecure or loss-prone transmission methods such as emails..

The letter contains a standard text with freely configurable placeholders which the system fills with the correct data when it is sent.

The recipient receives a clear compilation of all documents sent, can add comments or notes, and then decides whether to approve or reject the content. The system automatically records the response, assigns it to the original letter, and can trigger further work steps or approval processes.

AI-supported document chat for quick responses

An integrated document chat ensures smooth collaboration between suppliers, manufacturers, and customers. All involved can ask specific questions about extensive documents in a manual, such as operating instructions, safety specifications, or test instructions. The AI searches the documents contained in the respective manual, filters out the relevant information, and provides a precise, understandable answer in natural language in a matter of seconds. This reduces misunderstandings and speeds up feedback in the coordination process.

Digital signature for approved documents

Suppliers, manufacturers, and customers can digitally sign approved documents (e.g., legally relevant documents) directly as part of their approval. This speeds up approval processes, ensures legal reliability, and provides seamless traceability of all decisions.

The benefits at a glance

Structured generation of manuals does much more than just bring order to the documentation of technical systems. Here are the most important advantages at a glance:

- Clear structure

Instead of a loose collection of PDFs, you get a clearly structured manual with chapters, subchapters, and thematic sorting. This makes it easier to find information and classify it better, even with very high numbers of documents. - Fast access to relevant information

Thanks to smart search functions and structured filing systems, users can find the document or relevant information they need promptly. - Manual structures as reusable templates

With Fabasoft Approve, complete manual structures can be created once as templates and used again and again for similar projects. This saves time and ensures a uniform structure, especially for frequently recurring product types. - Better cross-company collaboration

All documents relevant to the manual are managed in one place and all associated workflows are clearly and transparently mapped. All parties involved, including external business partners such as suppliers and customers, know at all times what needs to be done and the status of each document. - Complete overview of all documents

Large technical systems in particular often require the management of hundreds or even thousands of individual documents. Systematic structuring and filter options help to maintain an overview at all times. - Reduced risk of contract penalties

Automated reminders support the timely transmission of required documents.

From document chaos to a clearly structured manual

Structured generation of manuals does much more than just bring order to technical documentation. It creates a new quality in the handling of information by linking content in a meaningful way, simplifying processes, and ultimately improving collaboration.

The added value is particularly evident in large projects with hundreds or even thousands of documents. The system not only documents, but also actively supports daily work and can be flexibly reused for similar future cases.