Thanks to the rapid advances of modern technologies like virtual reality (VR) and augmented reality (AR), new areas of application are constantly opening up along the entire value chain. Companies from the industrial environment are increasingly recognizing the added value of VR and AR and are using these to optimize their workflows and meet the requirements of Industry 4.0.

Virtual and augmented reality in focus: An overview

Virtual reality (VR) refers to a technology that allows users to immerse themselves in completely virtual 360-degree surroundings with the help of special VR glasses. Since the eyes are completely enclosed, the user is no longer aware of the real world, making computer-generated alternate realities a particularly immersive experience.

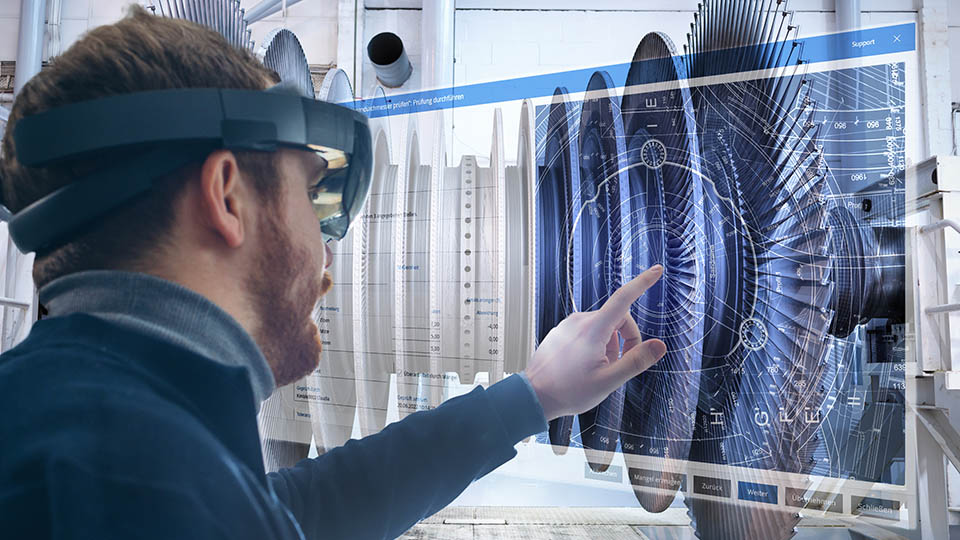

Augmented reality (AR) represents an artificially augmented reality in which digital information, e.g. texts, graphics, or entire 3D objects, can be superimposed on the real surroundings of the person using it. This information is visualized by means of AR glasses as well as cameras and displays on smartphones or tablets.

The distinction between virtual and augmented reality

The main difference between the two technologies lies primarily in the user experience. While VR creates a completely virtual environment that transports the user into an alternate reality, AR augments the real world with digital information by embedding it directly into the surroundings.

Key technologies for the advances in Industry 4.0

The use of virtual and augmented reality in the industrial environment opens up a range of novel opportunities to optimize processes along the entire value chain. Depending on the technology used, the immersive or interactive environments help improve the quality and accuracy of workflows, leading to more efficient execution of multi-faceted tasks.

Virtual reality is especially useful in Industry 4.0, as it can visualize products or processes that are still in the planning phase. In this way, virtual products can be tested from all angles and checked for errors even before completion. This approach reduces costs and helps companies make more qualitative decisions.

Another advantage of these technologies is that they enable rapid error detection and correction. This is prompting more and more companies to use them in quality management.

How VR and AR are making quality management more effective

Virtual and augmented realities are increasingly establishing themselves as an important factor in quality management. This is due mainly to the immersive 360-degree environments as well as the visualization of interactive information, which enable the efficient execution of established processes such as quality control. The virtual products or processes help to identify and eliminate sources of error at an early stage, which in turn leads to an increase in product quality.

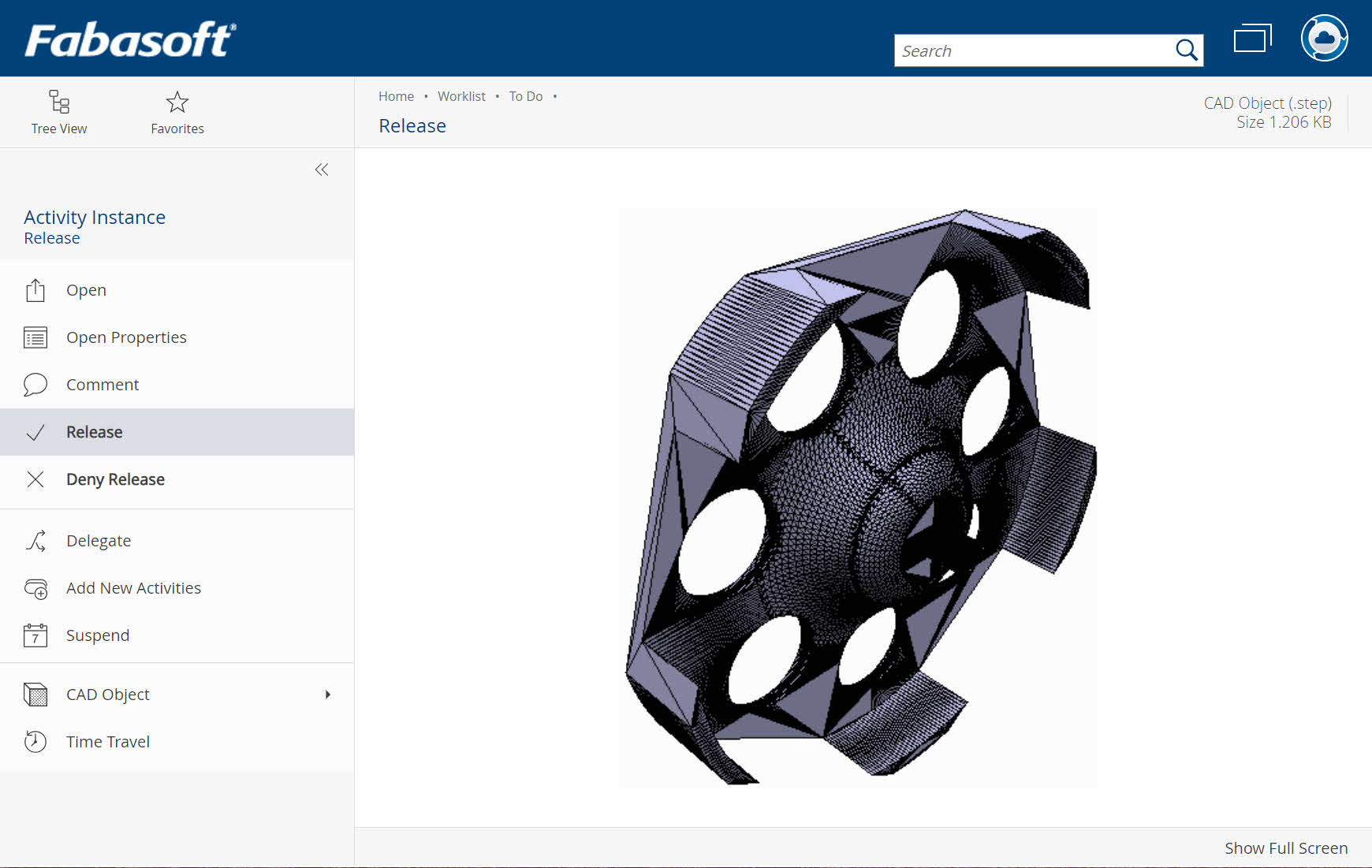

Such applications are supported by a smart Data and Document Management System (DMS) which manages relevant information in one place, ensures that it is up-to-date and secure, and documents all qualitative processes in a traceable manner.

The DMS system Approve on Fabasoft PROCECO offers seamless VR and AR integration. This results in a wide range of important application areas for quality management:

Virtual quality control

The integration of a virtual or augmented reality application into a DMS enables a virtual and interactive visualization of products or facilities, thus allowing a comprehensive quality control.

One conceivable use case is the inspection of an electric motor. The person inspecting the motor examines it virtually for any quality problems and can take immediate action without physically accessing it. During the process, the data and document management system ensures that all quality requirements are met.

Use of a “digital twin”

A DMS can be used to manage digital twins – i.e. virtual images – of products, facilities, or processes. Users then employ these digital twins in VR or AR applications to provide an immersive or augmented representation of real objects.

For example, a virtual machine that exists in parallel with the real one is maintained remotely using VR. The person performing the inspection compares the target/actual values and performs the necessary measures on the real machine.

Processing of digital checklists

A smart data and document management system provides a secure environment in which digital checklists can be created, managed, and updated. The persons performing the inspection then access these checklists directly on the shopfloor or in the incoming goods area and work through the individual points virtually, while the display of the glasses used shows visual instructions or assistance. This enables efficient and precise checking of the required tasks.

Visualization of 3D models

The integration of VR and AR applications in a DMS allows users to access 3D models (e.g., CAD data of facilities, machines, or pumps) using special glasses and visualize them in a virtual or augmented reality.

As a potential use case, users view a facility in its three-dimensional representation where they can examine individual components such as parts to be inspected in more detail. With this approach, potential weaknesses or optimization opportunities can be identified quickly and easily.

Illustration: Users inspect a 3D object in three-dimensional space using VR glasses and then approve it.

The DMS takes over the storage and management of such 3D models as well as access to any accompanying documentation, instructions, or test records that are linked to the objects.

Quality Management 4.0: The future belongs to VR and AR

Virtual and augmented reality are already playing a crucial role in industry by opening up new types of opportunities to optimize workflows. The use of these modern technologies leads to increased product quality through improved defect detection and correction and constitutes an important step towards Quality Management 4.0.

In addition, process efficiency, accuracy, and safety can be increased by networking with an intelligent data and document management system. Production processes optimized in this way ultimately ensure that industrial companies make more qualitative decisions, reduce costs and thus increase their competitiveness.

Would you like to discover more of Approve's features?

| Our experts will be happy to present the technical data and document management system Approve on Fabasoft PROCECO to you in a 60-minute live demo and answer all your questions. |